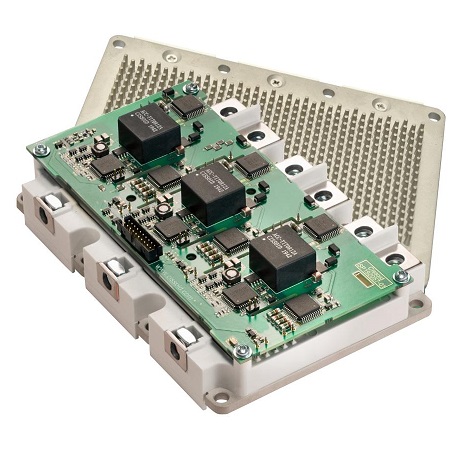

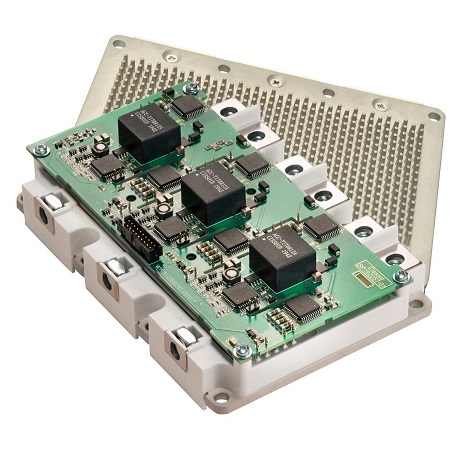

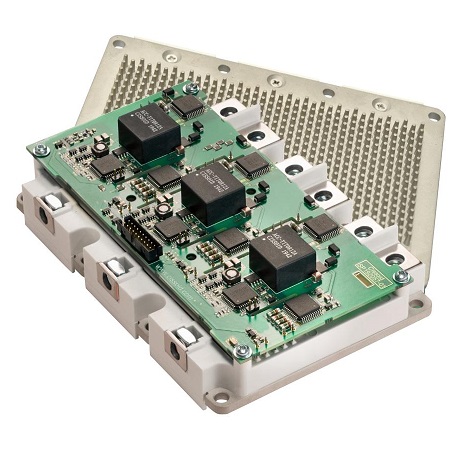

SiC Intelligent Power Modules

Our 3-phase 1200V Silicon Carbide (SiC) MOSFET Intelligent Power Module platform integrates the power switches and gate drivers, based on the CISSOID HADES2® chipset.

These modules address high power density converters offering a SiC power module designed for operation at a high junction temperature (up to 175°C). This solution gives access to the full benefits of SiC technology to achieve high power density thanks to low switching losses and high temperature operation.

Product Brief

The integration of the gate drivers together with the power module gives direct access to a fully validated and optimized solution in terms of switching speed and losses, robustness against dI/dt and dV/dt, and protection of the power stages (desat, UVLO, AMC, SSD, anti-overlapping).

The platform includes 3 modules with a pin fin AlSiC baseplate for liquid cooling, with diverse current ratings, allowing to find the best trade-off between cost, conductive and switching losses. The range also includes a flat AlSiC baseplate module for applications where liquid cooling is not an option.

Why?

Silicon Carbide (SiC) Power Transistors are now offering outstanding performance versus their silicon counterparts: Their low on-resistance at high blocking voltages, high switching speed and thermal performance allows system engineers to achieve significant gains in size, weight and efficiency for motor drives and battery chargers, in electric vehicles (EV) for example. The continuous drop in pricing is making SiC a mainstream technology. However, an important challenge for the adoption of SiC and other wide bandgap transistors in high power applications is the availability of well-optimized power modules as well as the learning curve in reliably driving them.

Intelligent Power Modules answer both challenges by offering highly integrated plug-and-play solutions, accelerating time-to-market and saving engineering resources. Transitioning to SiC is a long journey that can be shrunk drastically by adopting our SiC Intelligent Power Module platform, benefiting from more than 10 years of expertise in the development of SiC power modules and gate drivers.

Platform performance

- Power devices junction temperature: -40°C to +175°C

- Gate driver board ambient temperature: -40°C to 125°C

- Drain-to-source breakdown voltage: 1200V

- Low on resistance: 2.53mOhms to 4.19mOhms typical

- Max continuous current: 340A to 550A at Tf=25°C

- Thermal resistance: 0.15 °C/W typical

- Switching energy@ 600V/300A: Eon=7.5mJ to 9mJ/Eoff=7mJ to 7.4mJ

- Switching frequency: 50kHz max

- Isolation (baseplate - power pins): 3600VAC @50Hz (1min)

- Common mode transient immunity: >50kV/μs

- Low parasitic capacitance (primary-secondary): typ 11pF per phase

- Gate Driver Protections:

- Under Voltage Lockout (UVLO)

- Desaturation Protection

- Soft Shutdown turn-off (SSD)

- Negative gate drive (-3V)

- Active Miller Clamping (AMC)

- Gate-Source Short-circuit Protection

Support files

Type | Title | Link |

Product Guide | CISSOID SiC Intelligent Power Module Product Guide | |

White Paper | CISSOID-Dead-Time-Compensation-Scheme-IEEE-COMPEL-Paper-2024-04-18.pdf | |

Model | LTspice Model Library for CISSOID's SiC Intelligent Power Modules | |

Application Note | DC-Link Capacitors for CISSOID SiC Intelligent Power Modules Application Note | |

Application Note | CXT-PLA3SA-Mounting-cooling-recommendations-Application-Note-AN-202164-V2.3.pdf | |

3D Print File | CXT-PLA3SA Reference Cooler 3D Printing File for 3D printing in polymer material (PA12) | |

Step File | CXT-PLA3SA Reference Cooler 3D Step file | |

Step File | CMT-PLA3SB 3D Step file (flat baseplate) | |

Step File | CXT-PLA3SA 3D Step file (pin fin baseplate) |

Articles

Date | Source | Title | Type |

Apr 2024 | E-Mobility Engineering | The Pursuit of Power | |

Feb 2024 | Bodo's Power Systems | Accelerating mobility electrification beyond cars with modular and high power SiC traction inverters | |

March 2023 | Electronics Today |

CISSOID Cover Story, Electronics Today March 2023

| |

March 2022 | Compound Semiconductor China |

碳化硅模块的高温封装已成趋势

| |

Feb 2022 |

Electronics and Packaging

|

碳化硅器件挑战现有封装技术

| |

Feb 2022 | ECPE Workshop on Advanced Drivers |

Impact of Increasing Power Density & Switching Frequency on the Thermal Requirements & Design of Gate Drivers", at ECPE Workshop on Advanced Drivers for Si, SiC & GaN Power Semiconductor Devices

| |

| July 2021 | Power Electronics China |

车,不用SiC都不好意思叫电动出行

| link |

| May 2021 | Power Electronics News |

Liquid-cooled Modules with integrated 3-Phase SiC MOSFET

| link |

| Apr 2021 | Electronic Specifier |

SiC IPMs scupper range anxiety in electric vehicles

| link |

| Dec 2020 |

Online Wide Bandgap Conference

|

SiC MOSFET Intelligent Power Module Platform For E-Mobility Applications", presentation at Online Wide Bandgap Conference | |

Oct 2020

|

Elettrica Oggi Power

|

Modulo di Potenza Intelligente per la Mobilità Elettrica

| |

Winter 2020 |

E-Mobility Technology |

Intelligent Power Modules Accelerate Transition to SiC-Based Electric Motion

| |

|

June 2020

|

Bodo's Power Systems China Magazine

|

三相 1200V/450A SiC MOSFET 电动汽车智能 功率模块

| |

| May 2020 |

Bodo's Power Systems Magazine

|

A 3-Phase 1200V/450A SiC MOSFET Intelligent Power Module for E-Mobility

|